What is a pneumatic system?

The work of machines in industrial plants are made up of many systems. to help facilitate Increase the speed and efficiency of production which one of the systems that are widely used is the working principle of pneumatic systems, also known as compressed air systems. Pneumatics have many benefits. can be applied in all industrial sectors

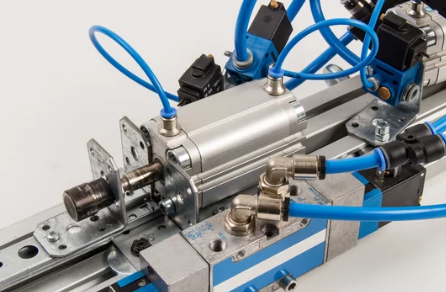

Pneumatics are systems that use compressed air to be delivered through pipes assembled with machines. This creates mechanical energy in the operation of various devices. Today’s pneumatic systems have a wide range of applications. Since the air cylinder system simple air motor to working in large machines together with the Automation system for automatic work

The advantages of pneumatic systems

1. Compressed air or pressurized air is highly explosive resistant. no explosion or burns like a flame

2. Pneumatic tool speed Provides a high working speed of 1–2 m/s.

3. The used high pressure or compressed air does not need to be reused. We can release compressed air into the atmosphere right away.

4. Compressed or high pressure air can be stored in a dedicated air tank. for continuous use

5. If the pneumatic device is overloaded, the device is safe.

6. This high pressure compressed air can be controlled. We can use other pneumatic devices. can be used to control such as pressure gauge or pressure control valve, etc.

7. The cleanliness of the pneumatic system is very good. because there is a set to adjust the air quality before use

8. The stroke of the connecting rod can be adjusted to short or long as needed.

9. Able to work at different temperature levels

Pneumatic components

- Air Compressor It serves to convert electrical energy or engine power into high-pressure compressed air.

- Heat Exchanger It serves to cool the compressed air from the working principle of the pneumatic system before use.

- Air Dryer It is responsible for preventing moisture or condensation in the system. in order not to damage the devices.

- Air Filter It has a duty to filter the air clean and trap the moisture obtained from the working principle of the pneumatic system before use.

- Service Unit It consists of a pressure reducing valve. Equipment for dispensing lubricants and equipment for air filtration has the function of filtering moisture adjust compressed air pressure and mix the lubricant to keep the equipment working as efficiently as possible.

- Pneumatic Directional Control Valve It is responsible for changing the wind direction through the control of the piston moving in or out. and speed control valve It is responsible for controlling the amount of compressed air to adjust the piston speed.

- Air Silencer It has the function of filtering the sound of wind from making noise while venting into the atmosphere.

- Air Cylinder The hero in the working principle of the pneumatic system that has it all. It is responsible for converting from wind energy to mechanical energy for machines to work.